Wearing a hat and shoe cover, we finally infiltrated the brewing site. Instead of looking through the glass aisle like a major manufacturer, you enter the "inside" where it is actually in operation. Therefore, it is dangerous to participate in shoes with heels or sandals. Wearing skirts and accessories is prohibited, so be prepared and participate.

The first thing you will be guided to is the "preparation room". Since it is about 40 degrees Celsius, there are large tanks lined up in a warm (no hot) room with the sweet scent of malt. Here you can sample the wort before mixing the hops. There was no bitterness derived from hops, and it was very sweet and rich.

[Yaho Aru 2] Employees can make beer freely !?

In one corner of the brewing room is a small brewing tank that was ordered from the United States. Employees can make beer with this tank! So far, many masterpieces such as shiso beer and sansho beer have been born. By the way, Mr. Yataro manufactures prune beer. "Probably the second worst in history" It seems that it became a "stray work".

Next, we went to the fermentation room, which was filled with the aroma of beer. Since the yeast of ale beer is set to 20 degrees, it feels chilly when coming from a room of 40 degrees. The amount of beer in one fermentation tank takes about 156 years even if you drink one can every day! You can see how it is fermenting.

The next room is lined with tanks to cool down and let the yeast lie down. Here, tasting the "brewed beer" taken out of this tank. Compared to the regular version of Yona Yona Ale, it had a refreshing and refreshing taste. It tastes like this before filtration!

Now, the finished beer is packed in cans and barrels in the filling room. Unfortunately, this day was a holiday, but I was able to meet only one "employee". His (?) Name is "Abe-chan No. 2". An arm for carrying boxed cans. Before the introduction of the arm, it was taken from the name of the veteran staff who played this role when it was done manually.

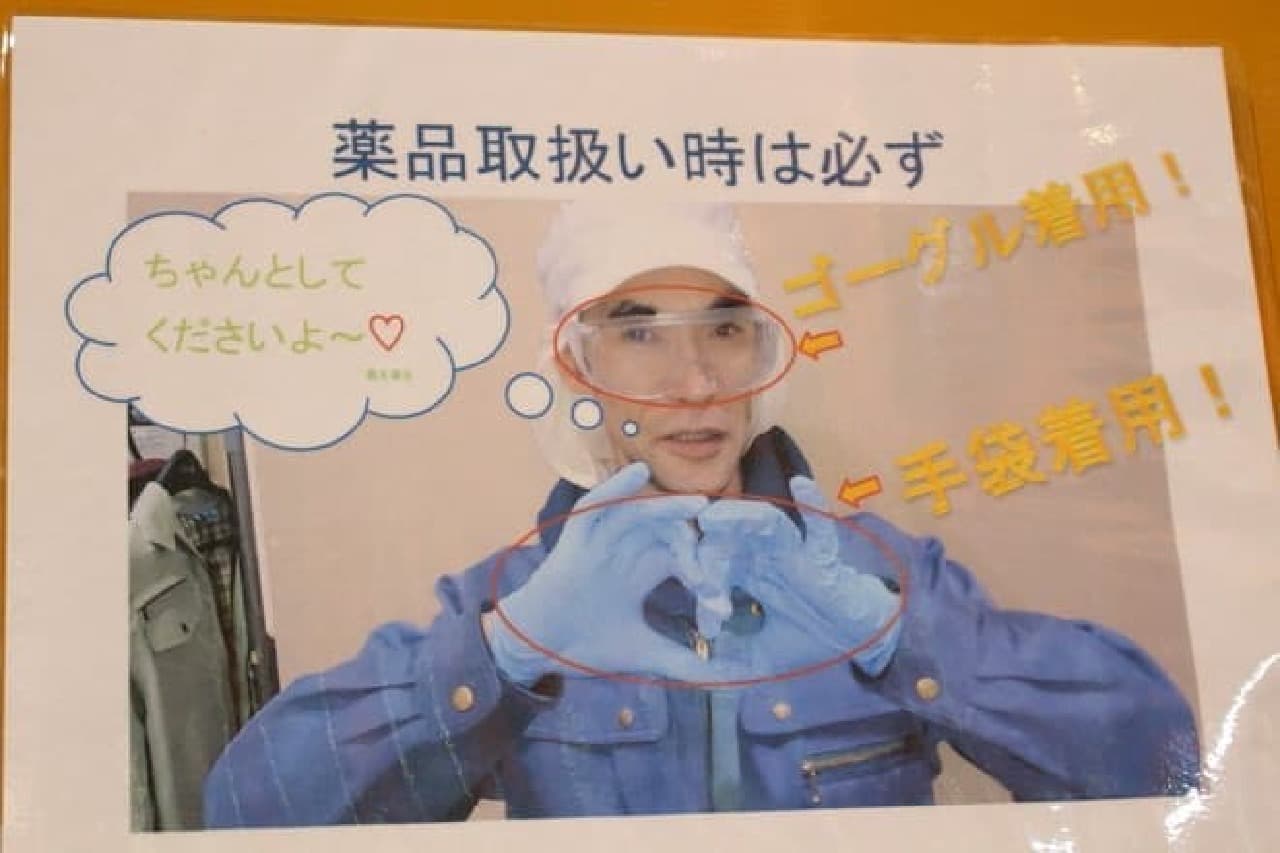

[Yaho Aru Aru 3] Bulletin full of material

Precautionary statement on the wall for "handling dangerous goods", sorting display written on the trash can, shift table of staff who processed the beer crown .. The bulletin board is studded with material about who made it. This flexible (?) Idea may have led to the making of interesting beer.

![[Report] Yona Yona Beer Garden 2015--Limited "Garden Session" is a refreshing drink](https://image.entabe.jp/upload/articles/8591/34d87ac34bdf7fcf3ebea15b760e3bdf_special.JPG)